C20, D35

ENEA Technology

ANALYSIS AND OPTIMIZATION OF CHEMICAL PROCESSES POWER-SUPPLIED BY SOLAR THERMAL ENERGY

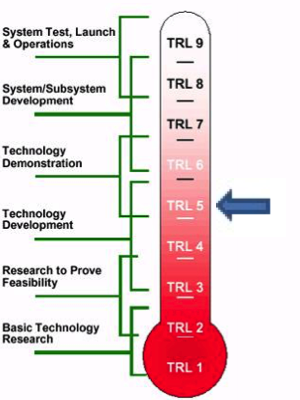

Technology Readiness Level (TRL)

4 ÷ 5

Innovations and Benefits

Medium- and high-temperature solar heat in industrial processes allows to significantly reduce CO2 emissions and free the thermal energy production cost from the fluctuation of fossil fuel price. Moreover, using different heat storage technologies can mitigate the limits imposed by the variability of solar resource. Yet, supplying chemical processes with solar thermal energy requires specific process and facility solutions, which ENEA can identify by combining its expertise on CSP plants and process simulation.

Use

ENEA has a long consolidated experience on hydrogen production processes using solar thermal energy; however, the approach and equipment developed so far allow to study and optimize the coupling of any kind of chemical processes with CSP plants up to 550°C. For each specific case the most adequate CSP technology can be identified, different schemes of integration between the chemical and solar plants identified, and the cost of the plant estimated through process simulation.

Applications and ongoing Activities

ENEA expertise in this sector has been consolidated thanks to its participation in several national and EU research projects mainly on the development of hydrogen production processes fed with solar thermal energy. Specifically: hydrogen production from water by thermochemical cycles (TEPSI, HyCycles and SOL2HY2 projects) and hydrogen production from carbon sources (CoMETHy project). In these projects, process analysis has always been developed along with pilot plants.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.