C25, C33

ENEA Technology

ANTI-WEAR AND ANTI-CORROSION COATINGS BY ELECTROSPARK DEPOSITION AND ELECTROPHORESIS

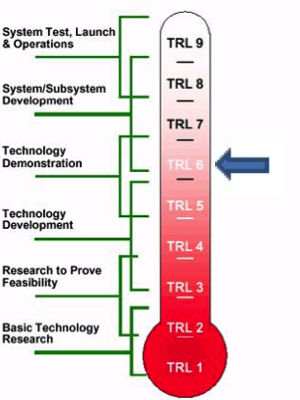

Technology Readiness Level (TRL)

5÷6

Innovations and Benefits

Application of anti-corrosion and anti-wear metal coatings by Elettrospark Deposition and process automation.

Improvement of the anti-corrosion properties of polymer coatings deposited by electrophoresis, through the use of nanocharges.

Use of low cost and easy scalability techniques.

Use

Anti-corrosion and anti-wear coatings to improve the performance of low quality materials and components.

Metal alloy depositions with new formulations, which can be optimized for use in highly corrosive environments.

Coatings of components and mechanical parts with complex geometries.

Repair of components with worn and damaged surfaces.

Applications and ongoing Activities

Prototyping of internal components of public transport vehicles (RINNOVA Regional Project).

Coatings based on Tungsten Carbide and Stellite on steel pump and turbocharger components (SMATI Project).

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.