C23, C28, C24

ENEA Technology

CO2 UPTAKE BY MEANS OF ENVIRONMENTAL BENIGN MATERIALS AND RENEWABLE PROCESS

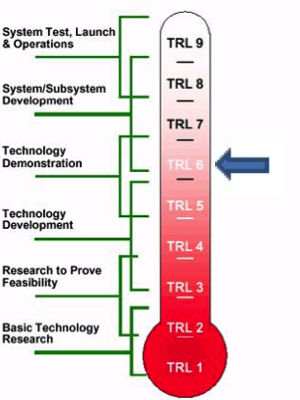

Technology Readiness Level (TRL)

6

Innovations and Benefits

The proposed technology is a disruptive process implementing the separation of CO2 by using non toxic naturally occurring material composed of calcium oxide which is regenerated at high temperature via renewable energy (concentrated solar energy). Conversely to the ammine process, the spent CO2 acceptor can be reused in other industrial processes (e.g. cement and steel making process) reducing the footprint of energy intensive industry and power production.

An European Science Foundation Research Infrastructure (ESFRI) named ZECOMIX (Zero Emission of Carbon with MIX technologies) is located at the ENEA research centre of Casaccia for the demonstration of integrated CO2 capture and reused of Ca based solid waste.

Use

Key impacts are in the energy intensive industries (e.g. cement, iron and steel making process); Reuse of solid waste produced in cement and steel industries in circular economy approach.

Applications and ongoing Activities

Open access pilot research infrastructure: ZECOMIX (Zero Emission of Carbon with MIX technologies); test rig test-rig VALCHIRIA for the reuse of Ca based solid wastes produced during the decarbonisation of fuel or flue gases. The Calcium looping process for the decarbonisation of power and energy intensive industry has been widely investigated in the 9.2 M€ EU funded project ASCENT (Advanced Solids Cycles with Efficient Novel Technologies) coordinated by ENEA in the 7th Framework Programme.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.