C26

ENEA Technology

DETECTION OF OXYGEN IN GAS MIXTURE BY OPTICAL EMISSION SPECTROSCOPY (D.O.E.S)

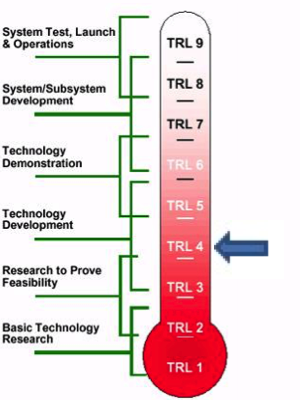

Technology Readiness Level (TRL)

4

Innovations and Benefits

In some industrial processes which use oxygen gas like, for example, in oxy-combustion plant, the monitoring and control of the amount of oxygen in the gases downstream is essential. In all the cases where temperatures and process pressures do not allow the use of conventional probes (such as lambda probes), oxygen monitoring can be performed by means of an experimental apparatus based on the analysis of the emission spectra of the gas mixture flowing in the sections of the plant.

The gas mixture flows in a chamber where a plasma is activated allowing that the emission spectrum of the gas mixture is acquired by means of optical fibers and compact spectrometers. Gas monitoring can be performed both in a qualitative manner (presence or absence of a certain species), or performed to determine the percentage ratios between the gaseous species present in the mixture. Currently, the system is designed for the detection of oxygen in gas mixtures.

Use

Detection of oxygen by means of the analysis of the emission spectra of a plasma lighted with the same gas mixture produced downstream of an industrial process. The apparatus can be interfaced to the plant section where the reactive processes take place. Response times can be less than 60 s. D.O.E.S. can be used in all applications where oxygen monitoring is required but without measuring the absolute quantity of the substance, but only its percentage ratio in comparison with other species.

The technology of D.O.E.S. can be extended to the detection of different gases in the mixture by measuring their relative change values.

Applications and ongoing Activities

Realization of a system called D.O.E.S (Detection of Oxygen by Emission Spectroscopy), calibration and laboratory test of the experimental apparatus with different gas mixtures. Ongoing software design that automatically provides the analysis of the gas mixture and the percentage content in oxygen.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.