C28, C30

ENEA Technology

DEVELOPMENT OF ADVANCED CO2 CYCLES FOR GAS TURBINES: EGR (EXHAUST GAS RECIRCULATION) TURBOGAS CYCLES

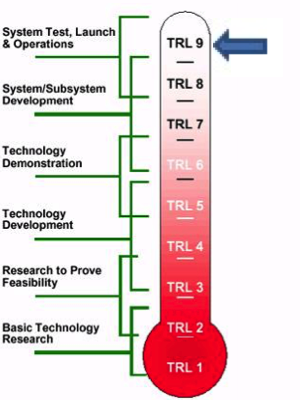

Technology Readiness Level (TRL)

7 ÷ 9

Innovations and Benefits

The EGR Turbogas cycles technology developed by ENEA is aimed at a significant NOx reduction and a higher thermodynamic efficiency in gas turbine based power plants.

The presence of a significant CO2 amount in working fluid, allows to reach higher turbine inlet temperature and consequently higher thermodynamic efficiency, limiting the increase of NOx production. For the same reason, NOx production at part load is significantly reduced, thus reducing the gas turbine minimum environmental load and, consequently, also reducing the operational costs related to the gas turbine parking load during flexible operation.

Due to the higher CO2 content in exhausts, the EGR gas turbines technology leads to lower sized capture facilities and a better effectiveness of the CO2 capture process. Consequently, the result is a better cost-effective CCS implementation, reducing both capital and operational costs.

Use

Stationary applications for power generation with high operational flexibility and lower emission. Naval propulsion, with significant emissions reduction using LNG (liquefied natural gas) or LPG (liquefied petroleum gas )as fuel.

Applications and ongoing Activities

The installation of the AGATUR platform is under completion. This large experimental facility allows the testing of the EGR technology, providing significant development elements.

Furthermore, important theoretical studies are currently developing and predictive ready-to-apply models have been developed.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.