E38

ENEA Technology

FEDORA - FEEDSTOCK RECYCLING OF MIXED PLASTICS

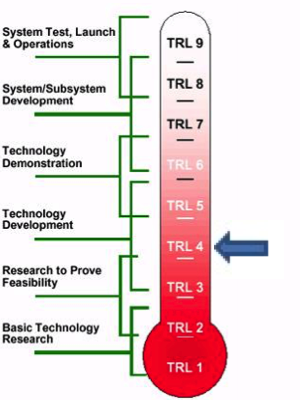

Technology Readiness Level (TRL)

4

Innovations and Benefits

Recovery of plastics from waste regardless of the polymer complexity and the degree of contamination. Development of thermochemical reactions with the use of waste ash as catalysts with the result of a double recovery of materials. Experimentation on type Y and ZSM5 zeolite catalysts with different pore diameter and Si/Al ratio.

Use

Production of crude oils to be refined for: thermoelectric power plant, cement factory, glassworks, central heating system.

Production of intermediates for synthetic chemistry.

Applications and ongoing Activities

Construction of a bench-scale pyrolysis reactor with two different geometries and volumes of the furnace complete with condensing unit for oil collection and gas sampling and operating up to 1000 °C in both isothermal and dynamic conditions.

Tests of thermal and catalytic pyrolysis on mixed plastics and on composite materials (microchips) of thermosetting polymer matrix with additives and metal fiber for the recovery of metals.

Upgrading of ash from waste of different origin to improve its specific area, the Si/Al ratio and the degree of acidity/basicity.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.