C20, E38

ENEA Technology

FRACTIONING LIGNOCELLULOSIC BIOMASSES FOR THE PRODUCTION OF RAW MATERIALS AND INTERMEDIATES

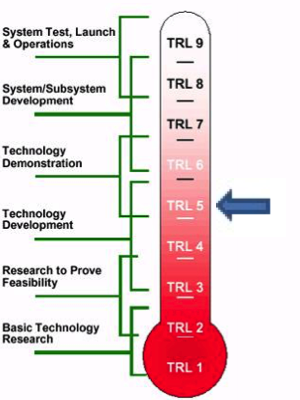

Technology Readiness Level (TRL)

5

Innovations and Benefits

ENEA technological platform operates on a pilot scale for the conversion of lignocellulosic biomasses to intermediates for the production of biofuels and green chemicals.

Compared to similar technologies, this platform offers:

- pre-treatment conditions versatility with respect to the feed material (wood, straw, numerous agro-industrial residues, etc.);

- rapid and solvent free pretreatment processes;

- use of additives in catalytic quantities in order to facilitate the biomass fractionation and the subsequent dowastream conversions process.

The platform consists of a steam explosion pre-treatment plant (300 kg/h); 2 extractors for the separation of cellulose, hemicellulose and lignin; a bioreactor for enzymatic treatments; cleaning modules with activated carbons and ion exchange resins; pilot scale concentration modules.

Use

The described technology is currently used for the production of second-generation sugars which can be fermented to alcohols to be used as biofuels (e.g. bioethanol, bio-butanol) or monomers for bio-polyesters (e.g. BDO), acids (e.g. lactic acid) of interest for the bioplastics, microbial oils (single cells oils-SCO). Microbial bio-oils can be trans-esterified for the production of biodiesel or de-oxygenated for the production of hydrocarbons (e.g. for the production of jet fuel). Microbial oils are also exploited in the production of monomers for bioplastics and bio-lubricants.

One of the secondary streams of this technology is lignin. It is a fraction of the biomasses constituted of a natural polymeric material, based on phenyl-propane units, that has great potential for applications in many sectors, such as the production of biofuels and bio-phenols, bioaromatics (starting molecule for numerous applications and new biopolymers).

The main target sectors involved for lignin-derived products are: biofuels, bio-polyesters, bio-adhesives, bio-composites, bio-polymers.

Applications and ongoing Activities

ENEA has been recently involved in "ALBE", "BIT3G" and "REBIOCHEM" projects of the National Cluster on Green Chemistry. The ENEA role in these projects mainly regards the optimization of the processes (pretreatment, fractioning, production, concentration and upgrading) providing sugars for the chemical industry. ENEA has worked on the production of sugars from "Guayule" biomass (in order to achieve 1,3 BDO by fermentation), and from "Cardo" biomass (achieving 1,4 BDO by fermentation).

Moreover ENEA was involved in pre-industrial activities in cooperation with Canadian customer "COMET BIOREFING" (partner of many European industrial stakeholders).

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.