C24

ENEA Technology

HYDROMETALLURGICAL PROCESSES AND TECHNOLOGIES FOR THE RECYCLING OF SPENT LITHIUM-ION SECONDARY BATTERIES

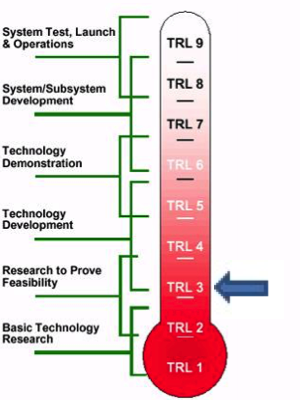

Technology Readiness Level (TRL)

3

Innovations and Benefits

Recycling of Lithium Ion batteries (LIBs) has become more and more important because of their widespread and constantly increasing use which also leads to an increased battery scrap generation (in both production as a well as end-of-life), which has to be recycled with regard to environmental and economical sustainability. LIBs safe disposal may become a serious problem due to the presence of flammable and toxic elements or compounds but at the same time, recycling of spent batteries may result in economic benefits which could be achieved in recovery of major components; in fact, LIBs contain high amounts of valuable metals, such as cobalt, aluminium, iron,copper, lithium, nickel and manganese. The most valuable metal is cobalt, which is contained in the battery electrode material as well as lithium which is not included in the list on critical raw materials, however it exceeds the threshold for economic importance.

Use

Design and development of innovative sustainable processes for the separation and recovery of valuable materials, such as anodic and cathodic ones (Li, Al, Cu, Co, Ni e Mn) from different spent LIBS.

Applications and ongoing Activities

The activities, performed within the "Electric System Research" project, allowed the development of a lithium recovery process with good yield, as well as the recovery of other LiFePO4 batteries components and materials; the proposed process was designed with a product centric approach and for this reason it involves a pre-treatment step that avoids the usual initial mechanical crushing and shredding of the batteries, which cause the relative loss or dilution of the elements and materials of interest. It is also a hydrometallurgical process, which allows the adoption of solutions with the lower environmental impact and the treatment of the individual batteries components enhancing their valorization and in the case of high toxicity, their safe disposal. Activities were carried out in collaboration with the Department of Chemical Engineering Materials Environment of the University of Rome "La Sapienza" which developed the pre-treatment step with safe opening and disassembling of the LiFePO4 batteries that were kindly supplied by the "International Battery Company" Srl .

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.