M72

ENEA Technology

USE OF MOLTEN SALTS AS THERMAL VECTOR FLUID AND HEAT STORAGE SYSTEM AT MEDIUM AND HIGH TEMPERATURE

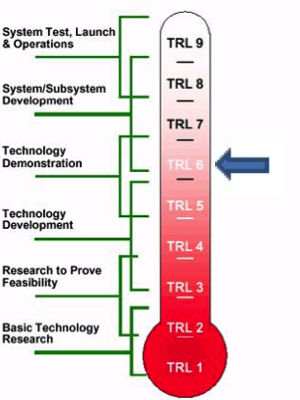

Technology Readiness Level (TRL)

6

Innovations and Benefits

Energy saving in industrial processes, with thermal recovery and production cycle optimization. Fossil fuel saving, lower costs and reduced environmental impact, simpler operation and facilities easier to use. These results can be attained by replacement of diathermic oils with molten salt mixes to obtain:

- higher operational process temperatures (up to 450 or 550°C) depending on the molten salt mix used;

- safer facilities (molten salt mixes are not inflammable, nor toxic) and in operation conditions their vapour tension is null, that is they are thermally stable and their chemical-physical properties are kept unaltered.

- lower supply and operation costs for the thermal vector fluid;

- lower environmental impact.

Use

Thermal recovery in medium-to-high-temperature industrial processes, thermal storage and production of vapour, heat and electricity. Replacement of diathermic oils in heat transfer and storage facilities.

Applications and ongoing Activities

Molten salt mixes for industrial applications have been characterized under several European (HYSOL, STS-MED, COMETHY, MATS) and national (METISOL, AdP) projects. Experimental activities have demonstrated that such mixes can be used as thermal vector fluids for heat storage systems at temperatures ranging between 300 and 550 °C. Corrosion tests have been performed for materials in molten salt fluxes and experimental facilities and prototypal heat exchangers have been realized that can be integrated within demonstration systems for generation, storage and use of thermal energy. MOSE, a molten-salt experimental facility, has been used to power the following facilities:

- hydrocarbons steam reforming facility with membrane reactor, for pure hydrogen and syngas production;

- natural gas reforming facility for the production of methane/hydrogen mixtures;

- GPL and/or biogas-powered back-up system for CSP facilities.

Molten Salt Experiment (MOSE) experimental facility

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.