M72

ENEA Technology

REALISATION OF PROTECTIVE COATINGS THROUGH HIGH TEMPERATURE SPRAY DEPOSITION/DETONATION GUN

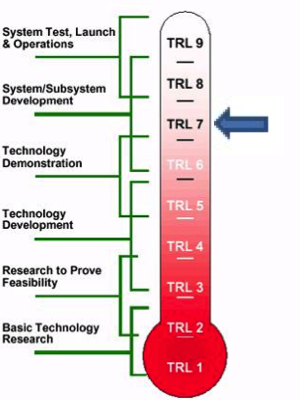

Technology Readiness Level (TRL)

7

Innovations and Benefits

By using the Detonation Gun, it is possible to realize surface coatings on components of different sizes, with various types of coatings, at ENEA laboratories.

Use

Realization of surface coatings.

Applications and ongoing Activities

The Detonation Spray device is capable of creating surface coatings on large components (on flat surfaces up to 1000mmx1000mm and cylinders with a maximum diameter of 400mm). The surface coatings are made of Al2O3/Al2O3 + intermediate layers on T91, AISI 316, AISI 304 or metal powders.

This technology is used in applications for fourth generation fission reactors.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.