C28, C29, C32

ENEA Technology

REALIZATION OF INNOVATIVE CERAMIC COMPONENTS AND MATERIALS FOR THE MANUFACTURING INDUSTRY

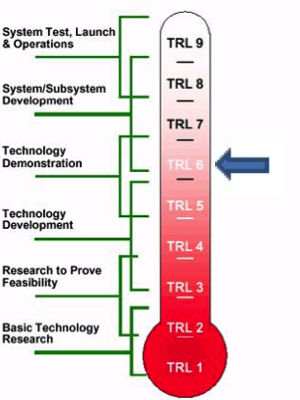

Technology Readiness Level (TRL)

5÷6

Innovations and Benefits

The use of HDE welding processes allows productivity increase, distortion reduction and increased energy efficiency in welded constructions and in similar processes of surface carryover and repair.

Use

Materials and components for the following industrial sectors:

- automated machines

- energy production and recovery

- automotive

- anti-ballistic protection systems

- biomedical

Applications and ongoing Activities

Development of materials based on silicon carbide for the construction of prototypes of heat exchangers.

Realization of braking components for the automotive sector.

Development of zirconia-based materials for the dental sector and for the orthopedic prostheses sector.

Qualification of the industrial production process of components for the automotive sector.

Activities carried out in European or national projects.

Collaborations with industries: Bart, Brembo, CeramTec, Ghimas, Kira Technology, Meccanotecnica Umbra, Rauschert Italia.

Patents: IT0001323827 - Procedure for joining ceramic materials, in particular ceramic materials based on silicon carbide;

IT0001362972 - Process for the realization of sintered material based on silicon carbide and aluminum nitride;

IT0001407390 – Ceramic material for dental prostheses.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.