C24

ENEA Technology

RECOVERY OF RARE EARTHS AND METALS FROM PERMANENT MAGNETS AND SPENT FLUORESCENT LAMPS

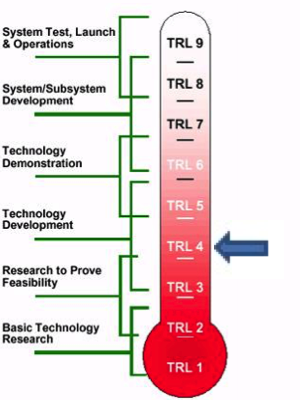

Technology Readiness Level (TRL)

4

Innovations and Benefits

The sustainability of the recovery processes is feasible when the highest amount of strategic raw materials is valorised, according to an approach where the entire waste is considered as a resource (Product-Centric Approach).

In case of complex matrices, such as fluorescent lamps and permanent magnets, the hydrometallurgical techniques represent an effective technology to separate and selectively purify the chemical species.

Hydrometallurgical processes were developed which allowed the recovery of:

• Sb, Cu, Y and Eu from spent fluorescent lamps.Cu and Sb are recovered through electrochemical methods in metallic form and with purity higher than 98%.

This process can be easily integrated into the conventional mechanical separation processes which allow the recovery of glass, ferrous and non-ferrous metals.

• Fe and Nd from permanent magnets.

Use

• Reintroduction in the production chain of strategic raw materials such as Y, Eu, Nd and of high added value elements such as Sb and Cu

• Reduction of the amount of waste containing hazardous components

• Natural resources conservation

Applications and ongoing Activities

Lab tests to verify the efficiency and the recovery yields of the investigated processes.

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.