C26, E36, J62

ENEA Technology

SYSTEM FOR THE AUTOMATED MANAGEMENT OF BIOLOGICAL WASTEWATER TREATMENT PLANTS

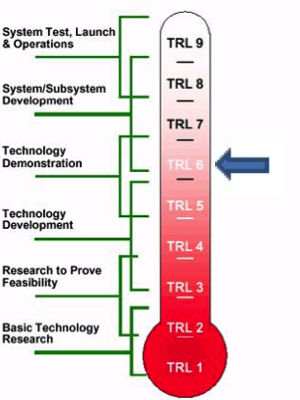

Technology Readiness Level (TRL)

5÷6

Innovations and Benefits

Low-cost system for the control and automated management of biological wastewater treatment plants (predenitro/nitro scheme). The system was patented on 12/16/2015 with PCT extension requested on 12/16/2016. With the use of this system, the energy efficiency of the plant aeration system and the efficiency of the nitrogen removal process are increased.

Use

The system, which needs to be installed on the purification plant, includes:

- measurement and acquisition of pH signals, redox potential (ORP) and dissolved oxygen (DO) inside the process tanks (Probes modules and Data Acquisition)

- control and automatic adjustment of air flow and of inside, external and overflow recirculation flow rates (Actuators and Controller modules)

- the processing of the acquired signals to implement the plant management policies and the process automatic control strategies (Management Policies and Control Strategies modules).

The control logics used implement a variable set-point-regulation of the air flow rate supplied by the blower, calculated according to the input load, and a modulation of the internal recirculation flow, defined according to the operational status reached by the denitrification process. The first one allows to reduce the consumption of the compressor up to 30%, while the second one always guarantees a good efficiency of the denitrification process.

Applications and ongoing Activities

The system was first tested on a laboratory-scale plant, fed with synthetic wastewater and in a temperature-controlled environment and then extended to a pilot-scale plant located near a municipal sewage treatment plant, fed with real wastewater. The system was monitored by measuring indirect signals (pH, ORP and dissolved oxygen) and direct signals (ammonia, nitrates and suspended solids). To guarantee the control system features of modularity, scalability, integration and interoperability, the Service Oriented Architecture (SOA) model was used, with the aim of facilitating the sharing and integration of services and supporting the development of distributed applications.

The architecture, represented in figure 1, is based on ESB (Enterprise Service Bus), a middleware that allows communication and routing of services between the modules.

Currently, collaboration agreements are underway with purification plant operators for the testing and validation of the system on real plants at various scales. In particular, the first test will be carried out on a plant of the multi-utility HERA SpA, in the province of Bologna.

Further information to: http://www.cross-tec.enea.it/?li=en&q=2&k=155&TR=D

“If you are interested in this technology/service, please send a message to eneaperlinnovazione@enea.it, by specifying the title of the technology/service of your interest, the reason for your request and your contacts or the contacts of a person from your organization/company.