Energy: Japan, “heart” of the JT-60SA fusion reactor assembled with Italian-made technology

15/11/2018

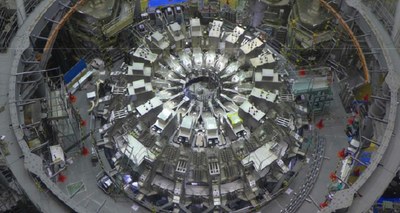

The assembly of the toroidal magnetic system of the JT-60SA fusion experimental reactor, the 'heart' of the plant, was completed in Japan thanks to the supply of 20 high-tech coils, of which 10 were manufactured in Italy. The announcement was made today during an event at the ENEA Headquarters in Rome, in which the Italian technological contribution to this new generation of nuclear fusion machines, expecting the first plasma in 2020, was illustrated in detail.

The assembly of the toroidal magnetic system of the JT-60SA fusion experimental reactor, the 'heart' of the plant, was completed in Japan thanks to the supply of 20 high-tech coils, of which 10 were manufactured in Italy. The announcement was made today during an event at the ENEA Headquarters in Rome, in which the Italian technological contribution to this new generation of nuclear fusion machines, expecting the first plasma in 2020, was illustrated in detail.

The assembly of the toroidal magnetic system of the JT-60SA fusion experimental reactor, the 'heart' of the plant, was completed in Japan thanks to the supply of 20 high-tech coils, of which 10 were manufactured in Italy. The announcement was made today during an event at the ENEA Headquarters in Rome, in which the Italian technological contribution to this new generation of nuclear fusion machines, expecting the first plasma in 2020, was illustrated in detail.

The JT-60SA reactor was developed as part of the Broader Approach scientific cooperation agreement between the EU and Japan, which saw the Italian research and industry at the forefront of hyper-technological components production. A result made possible by the synergy between ENEA and Consorzio ICAS, of which the Agency is coordinator, the companies Walter Tosto, OCEM Energy Technology, Poseico and ASG Superconductors of the Malacalza family (in whose plants in Genoa they were assembled) and the Ministry of Economic Development, which financed the entire supply through the National Electric System Research.

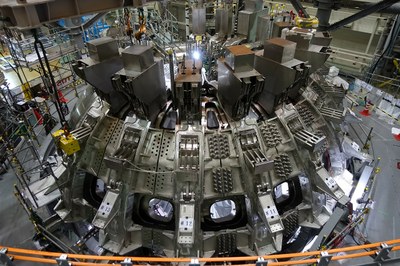

The superconductor coils are an engineering work with unique characteristics, starting from their size: 16 tons of weight for 8.5 meters of length and 4.5 meters of width. Thanks to these hi-tech Italian components and those made in France by the CEA, the Euro-Japanese plant will be capable of reproducing the reaction which has ben fueling the Sun and the stars for billions of years; the new magnetic system, thanks to superconductivity, will in fact be able to contain the plasma at a temperature of 100 million degrees Celsius to produce inexhaustible and environmentally sustainable energy.

The superconductor coils are an engineering work with unique characteristics, starting from their size: 16 tons of weight for 8.5 meters of length and 4.5 meters of width. Thanks to these hi-tech Italian components and those made in France by the CEA, the Euro-Japanese plant will be capable of reproducing the reaction which has ben fueling the Sun and the stars for billions of years; the new magnetic system, thanks to superconductivity, will in fact be able to contain the plasma at a temperature of 100 million degrees Celsius to produce inexhaustible and environmentally sustainable energy.

In addition to the supply of the coils and 20 containment boxes ENEA, together with its Italian partners, in the framework of Broader Approach, took care of the design and manufacture of other Tokamak components of great technological and industrial interest, such as the power system; in addition, it took part in the design and construction of the IFMIF (International Fusion Materials Irradiation Facility) neutron source which, thanks to an intense flow of high energy neutrons (up to 14MeV) will allow to test the new materials for fusion reactors.[1]

|

|

|

This hi-tech 'doughnut' will be at the heart of the Euro-Japanese fusion energy experiment which will prepare the way for ITER, the experimental reactor under construction in France, expected to start operating in 2025 thanks to the collaboration among the European Union, the United States, Russia, Japan, China, India and South Korea.

- Representatives of Italian industry receive ENEA recognition from Fusion for Energy and QST Rokkasho Fusion Institute

Italian excellence

Italy’s contribution to the main international research programs on fusion (ITER, DEMO and Broader Approach) is currently quite significant and our Country is one of the main partners of the European agencies (EUROfusion and Fusion for Energy). ENEA participates in these initiatives providing the expertise of its Fusion and Nuclear Safety Technologies Department at the Frascati and Brasimone Research Centers, world centers of excellence with state-of-the-art equipment. The traditional activities, dedicated above all to plasma physics, have gradually evolved towards a complex system of physics, technology and engineering, which sees the Agency as the protagonist and coordinator of the national fusion research program. Significant contributions have been provided in the fields of superconductivity, plasma interfaced components, neutronics, security, remote handling and plasma physics. Moreover, ENEA scientists were among the first to set up plants for the study of magnetic confinement plasmas, fusion machines such as the Frascati Tokamak (FT) and the Frascati Tokamak Upgrade (FTU); so far, research activities on fusion have generated over 50 patents over the past 20 years, with significant repercussions on the development and competitiveness of national industries.

A new technological challenge

At the ENEA Frascati Research Center, near Rome, the Divertor Tokamak Test (DTT) science and technology hub will shortly be established, one of the most advanced projects in the field of nuclear fusion research at the global level, which involves 1500 highly skilled workers and an estimated return of 2 billion euro with an investment of about 500 million euro.

[1] Italy supplied a total of 10 coils (8 installed in the plant and two spare) and 20 containment boxes, manufactured also for the 10 coils built by France. Italian components were given the names of the young daughters of the researchers, as a symbol of the passion for knowledge and an eco-friendly development (Roberta, Laura, Eleonora, Sofia, Giaele, Valeria, Margherita, Sandra, Silvia and Francesca) .