Innovation: ENEA develops new biodegradable and smart materials

12/3/2020

Possible applications in food packaging, furnishings and transport

"Smart" biofilms that change color in presence of food deterioration or prolong their expiration date; 100% biodegradable and compostable composite materials. These are the new "green plastics" developed by researchers at the ENEA Brindisi Research Center for possible applications in food packaging, furnishings and internal coatings for means of transport.

"Smart" biofilms that change color in presence of food deterioration or prolong their expiration date; 100% biodegradable and compostable composite materials. These are the new "green plastics" developed by researchers at the ENEA Brindisi Research Center for possible applications in food packaging, furnishings and internal coatings for means of transport.

Bioplastics are obtained from the transformation of sugars contained in corn and beets, while biocomposites are obtained by adding to the bioplastic additives from the processing waste of agro-food sectors typical of the area.

"We have been engaged for years in the challenge for sustainability, in line with the principles of enhancing local resources and the circular economy", Claudia Massaro, researcher at the ENEA Brindisi Research Center, pointed out. "We have focused on the development of solutions to reduce the environmental impact of containers at the end of their life, in line with the objectives of the European SUP (Single Use Plastics) directive which has banned the use of many disposable plastic products by 2021 and established, starting from 2025, a minimum mandatory 25% content of recycled material in plastic bottles, which will rise to 30% in 2030 ", Massaro said.

"We have been engaged for years in the challenge for sustainability, in line with the principles of enhancing local resources and the circular economy", Claudia Massaro, researcher at the ENEA Brindisi Research Center, pointed out. "We have focused on the development of solutions to reduce the environmental impact of containers at the end of their life, in line with the objectives of the European SUP (Single Use Plastics) directive which has banned the use of many disposable plastic products by 2021 and established, starting from 2025, a minimum mandatory 25% content of recycled material in plastic bottles, which will rise to 30% in 2030 ", Massaro said.

Smart and antimicrobial bio-films, developed in collaboration with the University of Salento, used substances of natural origin to make the film bioactive. "In addition to being biodegradable and compostable and performing the traditional function of containing and protecting food, these films can provide a specific response to the environment the containing film comes into contact with ," Claudia Massaro explained.

Smart and antimicrobial bio-films, developed in collaboration with the University of Salento, used substances of natural origin to make the film bioactive. "In addition to being biodegradable and compostable and performing the traditional function of containing and protecting food, these films can provide a specific response to the environment the containing film comes into contact with ," Claudia Massaro explained.

Thanks to the addition of cardanol oil (derived from cashew) and the molecule porphyrin, these bioplastics have strong antioxidant and antifungal properties, very useful in food packaging, as well as the ability to "signal" the food deterioration: by actively reacting with the internal atmosphere of the package, they change color according to the acid-base environment they come into contact with, thus becoming indicators of the state of conservation of the product. Furthermore, bio-films with antimicrobial properties have been developed using zinc oxide and aluminum, particularly suitable for prolonging the expiration date of products, in line with the objectives of food waste reduction of the UN 2030 Agenda.

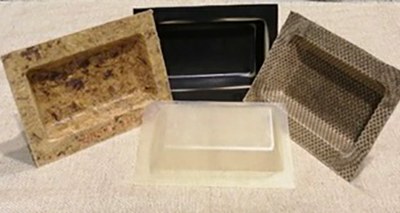

The new "green" biocomposite materials have been developed by adding to bioplastic fibers or additives of natural origin deriving from agri-food waste (flax, hemp, waste from olive oil and coffee processing). They have mechanical and fire resistance properties, useful for applications both in agri-food packaging and furnishings and interiors of means of transport (cars, trains and planes). In particular, the products made of bioplastic and waste from the oil sector have shown greater resistance to fire than "pure" bioplastic.

The new "green" biocomposite materials have been developed by adding to bioplastic fibers or additives of natural origin deriving from agri-food waste (flax, hemp, waste from olive oil and coffee processing). They have mechanical and fire resistance properties, useful for applications both in agri-food packaging and furnishings and interiors of means of transport (cars, trains and planes). In particular, the products made of bioplastic and waste from the oil sector have shown greater resistance to fire than "pure" bioplastic.

“Bioplastics and biocomposites at the end of their life undergo a degradation process that produces harmless or useful substances, such as fertilizers; they also have chemical-physical characteristics capable of completely replacing plastics of fossil origin in several applications ", Massaro concluded.

For more information please contact:

Claudia Massaro, ENEA – Laboratory of Functional Materials and Technologies for Sustainable Applications claudia.massaro@enea.it

Roberto Terzi, ENEA – Laboratory of Functional Materials and Technologies for Sustainable Applications, roberto.terzi@enea.it

Tommaso Marciano, ENEA – Laboratory of Functional Materials and Technologies for Sustainable Applications, tommaso.marciano@enea.it

“Technologies and Processes for Polymer Materials” – ENEA Brindisi Research Center