Training course for jewelry companies

8/2/2018

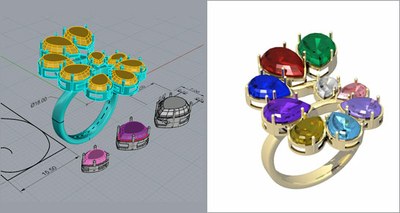

Innovating 3D and CAD technologies at the heart of the initiative conducted by the ENEA Bologna Research Center to train new professional figures aiming to join jewelry companies in the Arezzo district, in central Italy.

The activities are part of the project “Jewel and Design”, funded by the Regione Toscana, of which ENEA is coordinator and advisor in the sector of CAD/CAM technologies and conducts technology transfer activities of advanced 3D modelling, an essential element for gaining a competitive edge in both design and production costs.

The activities are part of the project “Jewel and Design”, funded by the Regione Toscana, of which ENEA is coordinator and advisor in the sector of CAD/CAM technologies and conducts technology transfer activities of advanced 3D modelling, an essential element for gaining a competitive edge in both design and production costs.

“For the training activities we used the equipment at the ENEA Proto-Lab: notably the 3D high resolution scanners for the creation of 3D files from real models and the high speed resin printers needed for starting the manufacturing phase of the collections”, Sergio Petronilli, Head of the Proto-Lab Laboratory, said. “Our generative modelling and inverted engineering techniques - Petronilli went on - allow to flexibly develop highly customized models which normal CAD modelling techniques can’t provide. Inverted technology enables us to rebuild the virtual geometry of a computer model avoiding physical contact and keeping jewels intact. This happens via the 3D scanning system which detects the coordinates of the points on the surface of the model, achieving an extremely faithful reproduction of the model.

These techniques allow companies operating in international markets to be much more competitive, improving their possibility of moving to a higher product segment.

“For the jewelry district of Arezzo - Petronilli went on - the possibility of acquiring advanced 3D design tools is the real added value of the Italian made collections because it enhances the creativity of our designers”.

As a first concrete result of the training course, nine participants have been hired in the companies of the Arezzo jewelry district and two in the industrial design sector, as evidence of the transversality of the technologies used.

According to the different sector of interest, the ENEA laboratory provides SMEs with the methodologies needed for including the new CAD/CAM technologies in the product development phase and optimize its production, in addition to integrating them with traditional methods ”Petronilli concluded.

The Arezzo jewelry district is the largest in Italy, with approximately 9thousand workers and 1200 companies. Proto-Lab is an operational unit of the Laboratory of Industrial Research CROSS-TEC of the ENEA Bologna Technology Hub, established with a Programme Agreement signed with the Regione Emilia-Romagna in 2010 and which contributes to the development of the Regional network for High Technology. Implemented with the resources of the European Social Fund, the training course, free of charge, was managed by Assoservizi, a training agency of Confindustria Toscana Sud, with the collaboration of the Siena University, Istituto Margaritone, Confartigianato, Confapi and private companies.

For more information please contact:

Sergio Petronilli, ENEA – Laboratory of Cross Technologies for Urban and Industrial Districts , sergio.petronilli@enea.it